Severe Service Slurry Control Valves

"At WPC we firmly believe that Control valves are not valves, but high precision instruments that contribute to the safety and operational success of our clients process plants" ™

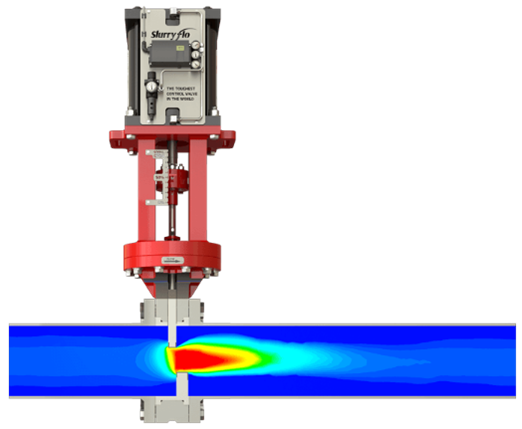

Modulating the flow of abrasive fluid is challenging. When slurry passes through a control valve, the restricted opening causes the fluid to accelerate.

This high-velocity media is then directed into the valve’s body and downstream pipe wall. The continuous erosion can result in frequent valve replacements, damaged piping and downtime.

In comparison to traditional ‘line of site’ control valves (such as ball, butterfly and pinch valves), which direct high velocity slurry towards the valve’s body and pipe wall, SlurryFlo’s patented trim design acts as variable orifice, centering the abrasive flow. This protects the pressure containing valve body and the integrity of the downstream piping.

SPECIFICATIONS

DIAMETER RANGE

Slurryflo control valves are available for 2 to 60 inch pipe diameters. (larger available of request)

PRESSURE CLASS

From low pressure gravity fed applications to systems with 1500 PSI, SAF manufactures valves to CWP, ANSI 150, ANSI 300 and ANSI 600 standards.

VALVE BODY & TRIM MATERIALS

As metallurgy is highly dependent on application specifications, our control valves are available in dozens of standard and exotic materials (e.g. Carbon steel, 316 Stainless steel, Hastelloy, SuperDuplex, Titanium, etc). There are no limitations on materials.